Understanding the Needle Gun

What is a Needle Gun?

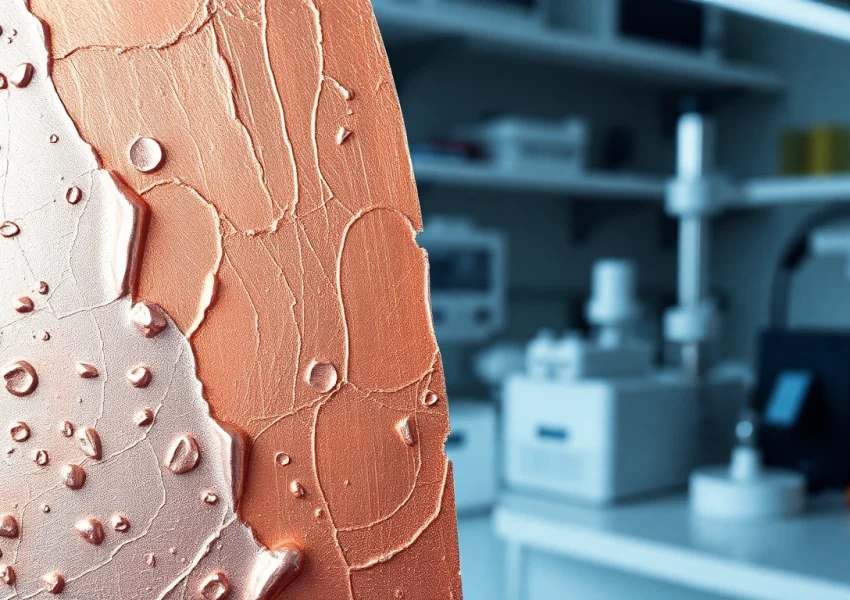

A needle gun, also known as a needle scaler, is an essential tool used primarily in metalwork to remove rust, paint, and other surface contaminants from metal surfaces. This device utilizes a series of rapidly vibrating needles to achieve its purpose, typically powered by either compressed air (pneumatic) or electricity. The vibrating needles strike the surface at a high frequency, dislodging particles without damaging the underlying material, making it an optimal choice for surface preparation in a variety of applications.

The versatility of the needle gun allows it to be utilized in various settings, from industrial factories handling heavy machinery to DIY projects at home. Understanding the workings and advantages of this tool can significantly enhance your efficiency and effectiveness in metal surface preparation.

Applications of the Needle Gun in Metalwork

The needle gun is predominantly used in fields where metal surfaces need to be cleaned or restored. Common applications include:

- Rust Removal: One of the primary uses of a needle gun is to eliminate rust from metal surfaces, thereby preventing further corrosion and extending the life of the equipment.

- Paint and Coating Removal: The tool effectively strips old paint, coatings, and other surface contaminants, making it ideal for renovation projects.

- Weld Preparation: Before welding, properly cleaned surfaces are crucial for effective joining. The needle gun prepares surfaces by removing mill scale and contaminants.

- Automotive Repair: Mechanics often use needle guns to clean metal components, ensuring they adhere to strict quality standards in vehicle maintenance and repair.

- Ship and Boat Maintenance: The marine industry frequently uses needle guns to maintain vessels, as they can effectively remove paint and corrosion in difficult-to-reach areas.

Key Components of a Needle Gun

Understanding the components of a needle gun is vital for effective usage. The main parts include:

- Needles: Typically made of hardened steel, these needles are the primary working elements that perform the striking action against the surface.

- Housing: The outer structure, which houses the mechanism that drives the needles, usually also includes the air or electrical components.

- Trigger: Allows the user to control the operation of the needle gun, engaging and disengaging as required.

- Grip Handle: Designed for comfort and control, ensuring the operator can hold the tool securely during use.

- Power Source: Depending on the model, this could be a pneumatic system requiring compressed air or an electric motor.

How to Use a Needle Gun Efficiently

Preparing Your Workspace

Before using a needle gun, preparation is crucial to ensure safety and efficiency. Follow these steps to prepare your workspace:

- Clear the Area: Remove any obstacles or unnecessary items from the workspace to prevent accidents and ensure easy movement.

- Protect Surroundings: Use protective coverings for nearby surfaces that may be damaged or affected by flying debris.

- Gather Necessary Equipment: Ensure you have appropriate personal protective equipment (PPE), including gloves, goggles, and hearing protection, as well as air compressors or electrical outlets available.

Step-by-Step Guide to Using a Needle Gun

Here’s a comprehensive step-by-step guide on how to use your needle gun effectively:

- Ensure equipment is in good working condition. Check the needles for any wear or damage.

- Set up your air compressor or plug in your electric needle gun, ensuring it’s functioning correctly.

- Wear your PPE to protect against flying debris and potential injuries.

- Hold the needle gun at a comfortable angle that allows you to access the area effectively.

- Begin the operation by pulling the trigger, guiding the needles across the surface to dislodge rust or paint.

- Use a steady motion, focusing on each area briefly to avoid damage to the substrate.

- Clean the area periodically to assess progress and ensure effectiveness.

- Once finished, turn off the tool and clean the workspace.

Safety Precautions When Operating a Needle Gun

Safety should always be a priority when operating a needle gun. Here are essential safety precautions to keep in mind:

- Wear Protective Gear: Always use safety goggles, gloves, and ear protection.

- Maintain Good Ventilation: Ensure your workspace is well-ventilated to avoid inhaling dust and debris.

- Keep Work Area Organized: A clutter-free workspace minimizes hazards and promotes safe operation.

- Inspect Equipment Regularly: Check for any signs of wear, damage, or malfunction before use.

- Follow Manufacturer’s Instructions: Always refer to the user manual for specific operational guidelines related to your model.

Choosing the Right Needle Gun for Your Needs

Pneumatic vs. Electric Needle Guns

When selecting a needle gun, one critical decision involves choosing between pneumatic and electric models. Each type comes with its advantages and disadvantages:

Pneumatic Needle Guns

Pneumatic needle guns are powered by compressed air and typically offer a higher rate of power and needle speed. They are generally utilized in industrial settings due to their efficiency and durability. However, they require a compressor and proper air connections, which could be a downside in some applications.

Electric Needle Guns

Electric needle guns, on the other hand, are more portable and easier to use in various locations. They do not require an air compressor and can be plugged directly into a power source. However, they usually have a slightly slower speed compared to their pneumatic counterparts, which may affect their efficiency in heavy-duty tasks.

Understanding CFM Requirements

Cubic Feet per Minute (CFM) is a crucial specification for pneumatic needle guns. CFM indicates the volume of air a compressor can deliver in one minute. Most needle guns operate efficiently at a CFM range of 8 to 16 at 90 PSI. It’s essential to match your needle gun with an appropriate air compressor equipped to handle the required CFM to avoid performance issues.

Top Brands to Consider

Several brands are renowned for their quality needle guns. Consider exploring options from these reputable manufacturers:

- Ingersoll Rand: Known for durability and performance, Ingersoll Rand offers a variety of pneumatic models.

- Chicago Pneumatic: A well-established brand providing affordable yet reliable needle guns for a range of applications.

- Powermate: Their electric models are ideal for automotive and small-scale jobs.

- Trelawny: Offers robust heavy-duty needle guns suitable for extensive industrial use.

Maintenance Tips for Long-lasting Performance

Cleaning and Care for Your Needle Gun

Proper maintenance of your needle gun is essential for ensuring longevity and optimal performance. Here are basic maintenance tasks to consider:

- Regular Cleaning: After each use, remove debris from the gun to prevent blockages and keep it operating smoothly.

- Lubrication: Apply lubricant as specified in the manufacturer’s recommendations to keep moving parts functioning efficiently.

- Needle Inspection: Regularly check needles for wear and replace them if they are bent or broken.

Identifying Common Issues

Recognizing potential problems with your needle gun can help prevent costly repairs or replacements later on. Common issues include:

- Reduced Power: This could be due to low air pressure or clogged needles.

- Excessive Vibration: May indicate worn-out needles or mechanical issues within the tool.

- Unusual Noise: Any grinding or rattling noises should be investigated promptly.

When to Seek Professional Repair

If you encounter significant issues that regular maintenance cannot resolve, seeking professional repair is advisable. Signs you should not ignore include:

- Persistent operational issues despite proper maintenance.

- Physical damage to the unit that cannot be repaired safely at home.

- Inconsistent performance affecting project efficiency.

Maximizing Efficiency with the Needle Gun

Techniques to Speed Up Rust Removal

To enhance the efficiency of your needle gun, consider these techniques for faster rust removal:

- Use the Right Needle Type: Select needles of appropriate thickness and length based on the material type and state.

- Adjust Pressure Settings: Optimize air pressure settings (for pneumatic models) to match the surface condition for quicker results.

- Implement a Systematic Approach: Work in systematic lines to ensure comprehensive coverage and prevent missed spots.

Combining Needle Guns with Other Tools

Sometimes, combining your needle gun with other tools can lead to even better results. For example:

- Wire Brushes: For initial rust removal or when working on heavily corroded surfaces, use wire brushes alongside the needle gun.

- Sanders: After using a needle gun, follow up with a sander for a smooth finish.

- Sprayers: Use paint sprayers to apply protective coatings efficiently after surface preparation.

Performance Metrics for Successful Projects

Establishing performance metrics can help gauge the success of your projects using a needle gun. Important metrics to track include:

- Time Efficiency: Measure the time taken for different tasks to identify areas for improvement.

- Quality of Finish: Inspect surfaces post-operation to evaluate the effectiveness and quality of the cleaning.

- Operational Costs: Monitor costs associated with tool maintenance, materials, and time spent on labor to ensure project profitability.